The Traction Avant Gearbox shortcomings

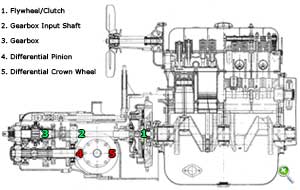

Now the Traction Avant was ahead of it's time back in 1934 with it's front wheel drive layout, but it differs from modern cars in that the layout is 'fore and aft' rather than 'Transverse' as pioneered in the Mini in the late 1950's so the gearbox hangs at the very front of the car below the radiator.

Now the Traction Avant was ahead of it's time back in 1934 with it's front wheel drive layout, but it differs from modern cars in that the layout is 'fore and aft' rather than 'Transverse' as pioneered in the Mini in the late 1950's so the gearbox hangs at the very front of the car below the radiator.

The design incorporates the differential into the gearbox housing itself and can fail quite dramatically if something should go wrong, as lots of unfortunate owners have found out over the years and gearboxes are one of the very few weakness in the Traction Avant's design.

When we bought OSL282 we knew the car had a new clutch and the gearbox itself worked well so we never planned to touch it as 'if it's not broke, don't fix it'!

However, 22nd July 2018, driving back from a classic car display, 2 miles from home when pulling away at a roundabout, there was a loud bang from the front end and some distinctly disturbing noises and serious vibrations when trying to put power to the wheels so we had the car recovered to home to avoid potentially causing any further damage.

At home, the drive shafts and hubs all appeared OK once the car was jacked up, but there was noise from the differential area when spinning the road wheels by hand so we suspected the worst. The design and layout of the small bodied Traction Avant however means visually checking the gearbox and differential require removal of the bonnet and radiator to get at the gearbox cover.

So we again had the car recovered, this time to 'Traction Repairs' in Morpeth and once James had the gearbox opened up my own initial diagnosis was confirmed, the problem was in the differential and the 'pinion' had failed.

Basically 2 teeth had broken off the Pinion which drives the Crown Wheel, fortunately the broken bits had fallen into the bottom of the bell housing and the gearbox casing appeared intact.

Now it is possible, but not always easy, to remove the gearbox with the engine in place, but refitting isn't, the engine does need to come out of the car so that the gearbox can be bolted to the Bell housing and get an oil leak free seal.

The Gearbox was quickly removed with the engine in situ and following James's recommendation went off by courier to Mark Harding at Devon Tractions 400 miles away, for a specialist gearbox rebuild. Mark has a lot of experience with Traction Avant gearboxes and his expertise is invaluable.

A Crown Wheel and Pinion set were required and had to be ordered from Jose Fransens in Belgium, as no one else had one and along with the gaskets, cost £769.00 alone.

Mark subsequently confirmed once it had arrived that having thoroughly measured and checked the gearbox, stripped, then steam cleaned it, there were no signs of any 'terminal' cracks in the casing, which is always a possibility on a Traction and not an uncommon occurrence. Whilst some so good news, however 1st gear had some wear and would also needed replacing, along with the bearings.

The gearbox parts image is from French Traction Avant specialist Pat2d

|

|

During our discussions Mark confirmed my own suspicion following examination of the bits of broken pinion that the differential pinion teeth that broke off had historic cracks which eventually spread, finally 'letting go'under load.

The gearbox apparently had been rebuilt in the past (before we acquired the car) but the Crown Wheel and pinion were not to Citroen's original design and the bearings were not renewed, so both may have contributed to the failure.

I know that the car had been 'bumped' at the front some time in the past as the front left lower suspension arm was bent so suspect the differential took some undue load at the same time causing the initial cracks which eventually led to the 2 teeth shearing off.

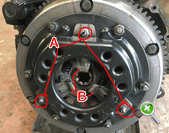

Some images of the damaged and worn parts are shown below after the gearbox was returned.

The gearbox was rebuilt by Mark Harding at Devon Tractions and as well as the new Crown Wheel and Pinion and a replacement 1st gear, Mark fitted 6 new bearings and made a new bush for 2nd gear and a Celron thrust washer plus made new gaskets and measured and set all the end floats and tooth clearance on the gearbox and differential as well as giving it a couple of coats of Epoxy 223 Middle Bronze paint.

Rebuild cost including labour and new bearings etc. etc. £710.85

The broken teeth..... Not even our Dentist could reinsert those!

Whilst the engine was out of the car and the gearbox removed, it made sense to clean, check and adjust the clutch and fit a new release bearing. Adjusting the 3 'fingers' on the clutch proved to be problematic due to wear on the clutch plate and the size of the new release bearing.

Whilst the engine was out of the car and the gearbox removed, it made sense to clean, check and adjust the clutch and fit a new release bearing. Adjusting the 3 'fingers' on the clutch proved to be problematic due to wear on the clutch plate and the size of the new release bearing.

Basically the release bearing was travelling to far when depressed so fouling the pressure plate at a setting of 23mm (original setting) and 24mm. At 26mm it meant that the clutch pedal would sit to high and would result in the clutch quickly wearing out so a compromise setting of 25mm was made by James. It had to be done before the unit was back in the car as the gearbox needs to be removed to access the clutch and adjust the 'finger' settings.

A new camshaft pulley (which drives the water pump and alternator) was also fitted along with new bearings to the shaft and the worn 'bowden coupling' replaced.

Engine and gearbox oil as well as the coolant were all replaced and a new fan belt fitted to complete the overhaul.

Last Edit: 13th August 2018